Redefining The Business with Chemicals: The Payment for The Utility of Chemicals and Not for The Amount

Let’s look at the business of chemicals: the main interest of chemical users is not to buy and possess chemicals products. They are rather interested in the best solutions for their product (performance, quality) and/or processes where chemicals are applied.

Key Words: Service-based economy, utility of chemicals, chemical industry, performance-based business model, Chemical Leasing.

The shift to a service-based economy is leading to the development and application of new business models in which the service component of products provides the added value to customers and as such becomes the essential part of business relations. Service-based business models facilitate recycling, take-back and reuse. Consequently, such models reduce resource consumption, waste and emissions to the air and water. At the same time, these models contribute to more cost-efficiency for businesses.

Let’s look at the business of chemicals: the main interest of chemical users is not to buy and possess chemicals products. They are rather interested in the best solutions for their product (performance, quality) and/or processes where chemicals are applied.

They are rather interested in the best solutions for their product (performance, quality) and/or processes where chemicals are applied.

For example, a producer of automotive parts needs solvents to clean and degrease them: the company is interested in the cleanliness of parts (product performance) as well as the improvement of process productivity (shorter cleaning cycle – higher process productivity). The company is interested in paying for the utility of chemicals and not for the amount of solvent used.

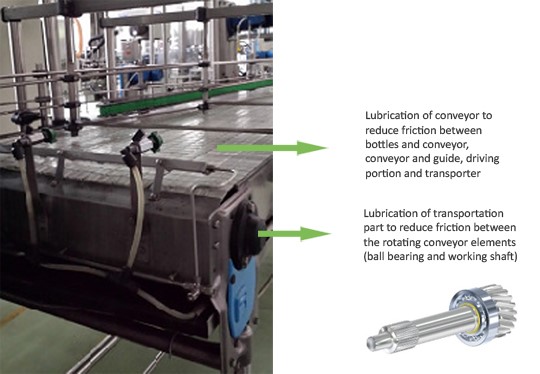

Let’s take the example of a beverage company and discuss this in more detail. It has a packaging line with a lubrication process and needs the conveyor to operate smoothly in order for the friction to be uniform and keep bottles from falling. How to achieve this? The company might buy and apply more lubricant chemicals, hoping that overdosing would improve the performance of the conveyor. Lubrication is not the company’s key competence, and now it faces another problem: more foam formation and the overflow of the tray.

As a result, the company now has a slippery floor and increased environmental, health & safety (EHS) risks.

A possible solution to optimize the company’s production process would be to find a chemical supplier with an expertise in lubricants, that can offer a performance-based business relation and establish a payment linked to the performance of the process where chemicals are applied. The unit of payment, in this case, could be based on the number of working hours of the conveyor working smoothly and without interruptions. This functional payment aligns the interests and motivations of both business partners. Both are interested in process optimization and efficient use of chemicals. The lubricant-supplying company brings its know-how on a more efficient application of lubricants and technical measures to improve the productivity of the lubrication process (for example substituting the water-diluted lubricant by a dry and less hazardous one, installing a different kind of nozzles and new dosage system).

This functional payment aligns the interests and motivations of both business partners. Both are interested in process optimization.

This form of cooperation driven by a new business logic leads to process improvement as the graphic below shows and helps achieve the win-win situation for both businesses and for the environment.

The graph shows the coefficient of friction before and after the implementation of the performance-based business model (Chemical Leasing). The graphic is based on figures received from a real case study.

As the examples show, chemical users change their focus from product to service, paying attention to the utility of chemicals. These users are interested in services that support their business process optimization, help improve the economic, social and environmental performance and achieve better sustainability.

The growing customer demand of sophisticated solutions that support chemical operations and profitability leads to a change of the business paradigm: the utility of a chemical and desired performance of a process/product become the centre of the buying process. The chemicals’ services to be rendered become an essential part of business relations, modifying the way of doing business with chemicals.

Performance-based business models (also called “performance-based contracting”) are a response to market demand: the customer pays for the utility of the product and not for its quantity or volume.

Chemical Leasing is a performance-based business model for sustainable chemicals management. Performance-based business models related to chemicals can be called and branded differently in companies, even if they are similar to Chemical Leasing.

Performance-based business models related to chemicals can be called and branded differently in companies, even if they are similar to Chemical Leasing.

The two figures below show the difference between the conventional business model and a performance-based business model (such as Chemical Leasing). Chemical suppliers/traders are striving to achieve a higher profit and grow their market share, but this target can be achieved differently as follows:

From the conventional business model towards a performance-based business approach

Are you interested in learning more the performance-based model of Chemical Leasing?

- Visit the Chemical Leasing website www.chemicalleasing.org

- Check the next opportunity to attend the Chemical Leasing webinar.

References:

- Chemical leasing website www.chemicalleasing.org. The website was developed under the UNIDO global Chemical Leasing programme.

- Denis Kuzniatsou, Performance-Based Contracts: Making the Shift from Products to Services

Source: The article was published for the first time in: www.linkedin.com/pulse/redefining-business-chemicals-payment-utility-amount-maria-grineva

Image copyrights: Shutterstock

Vojislavka Satric

An experienced chemical engineer, international expert on sustainable chemicals management and Chemical Leasing, author ofscientific articles on green chemistry and Chemical Leasing, the winner of several Chemical Leasing awards.

Maria Grineva

An external consultant of UNIDO, experienced in the coordination of industrial development projects, PR and communication solutions. Conceptualized and developed the web-version of the Chemical Leasing toolkit and IAMC toolkit. Communication manager for the Global Chemical Leasing Award 2020. Co-founder of Athenea International.

Picture 1: Conveyor lubrication

Picture 1: Conveyor lubrication