ABOUT THE MODEL

Chemical Leasing in Practice

Chemical Leasing is a performance-based (service-oriented) business model that shifts the focus from increasing sales volume of chemicals towards a value-added approach.

Chemical Leasing is a performance-based (service-oriented) business model that shifts the focus from increasing sales volume of chemicals towards a value-added approach.

In Chemical Leasing, the supplier no longer measures success according to the volume of chemicals sold. The supplier and the user both benefit because less chemicals are used when payment is linked to the functions performed. By aligning the interests of supplier and user, the volume of chemicals used is reduced, costs are cut, and each party increases its profits. Chemical Leasing creates a perfect business environment to tackle challenges in a changing global context.

The shift to a circular economy is leading to companies adopting new business models in which the performance and the service component of products provide the added value to customers and as such becomes the essential part of business relations. Performance-based business models facilitate take-back, reuse, and reycling. Consequently, such models reduce resource consumption, waste and emissions to air and water. At the same time, these models contribute to greater cost-efficiency for businesses.

Let’s look at the business of chemicals.

The main interest of chemical users is not to buy and possess chemicals. Rather, they are interested in ensuring that the chemicals they use deliver the best solutions for their product and/or processes.

For example, a producer of automotive parts uses solvents to clean and degrease the parts.

The company is interested in the cleanliness of the parts (product performance) as well as in the improvement of process productivity (shorter cleaning cycle – higher process productivity) which the solvent can deliver, not ownership of the solvent. In other words, the company is interested in paying for the utility which the solvent delivers and not for the amount of solvent it uses.

Let’s take the example of a beverage company and discuss it in more detail. It has a packaging line with a lubrication process. It needs the conveyor belt to operate smoothly and with as little friction as possible in order to keep the bottles from falling over. How to achieve this, keeping in mind that lubrication is not the company’s key competence? It could just play it safe, applying large amounts of lubricant chemicals to the conveyor and hoping that overdosing will maintain a satisfactory performance level. However, not only is the company buying more lubricant than it really needs, but it now faces another problem: excessive foam formation: the large amounts of foam produced overflow the catchment tray and fall to the ground. As a result, the company has a slippery floor and increased health and safety risks.

Another option would be to find a chemical supplier with an expertise in lubricants, which can offer a performance-based business relation and establish a payment linked to the performance of the process where the lubricant is applied. The unit of payment in this case could be the number of hours the conveyor works smoothly and without interruptions. This functional payment aligns the interests and motivations of both business partners. Both are interested in process optimisation. The beverage company gets what it ultimately wants: a smoothly operating conveyor belt. The lubricant supplier brings its know-how on lubricating processes, installing the technical measures required to improve the productivity of the lubrication process (for example substituting the original water-based lubricant with a dry (and less hazardous) one, installing a different kind of dosing nozzles and a new dosage system).

This form of cooperation driven by a new business logic leads to process improvement as figure 1 shows and helps achieve the win-win situation for both businesses as well as for the environment and health and safety.

Figure 1: Coefficient of friction before and after the implementation of the Chemical Leasing model

As these examples show, chemical users change their focus from product to performance, paying attention to the utility of the chemicals they use. These users are interested in services that support the optimisation of their business processes, help improve their economic, social and environmental performance and achieve better sustainability.

The growing customer demand for sophisticated solutions that support chemical operations and profitability leads to a change of the business paradigm: the utility of a chemical and desired performance of a process/product become the centre of the buying process. The performance to be rendered by chemicals becomes an essential part of business relations, modifying the way of doing business with chemicals.

Performance-based business models (also called “performance-based contracting”) are a response to market demand: the customer pays for the utility of the product and not for its quantity or volume.

Chemical Leasing is a performance-based business model for sustainable chemicals management. Performance-based business models related to chemicals can be called and branded differently, even if they are similar to Chemical Leasing.

The two diagrams in figure 2 show the difference between the traditional business model and a performance-based business model. Chemical suppliers are striving to achieve a higher profit and grow their market share, but this target can be achieved differently as follows:

Figure 2: The traditional business model vs a performance-based model

Let’s start by highlighting the following: The term Chemical Leasing is the name of a business model and is NOT the same thing as leasing of chemicals.

In leasing, the chemical remains under the ownership of the chemical supplier, and the chemical user pays only for its use. In contrast, in Chemical Leasing the user pays for the performance of the chemical. Contrary to leasing, the issue of ownership of the chemicals is of little relevance to Chemical Leasing because it does not influence the benefits of the business model.

For Chemical Leasing, the following aspects are of crucial importance to the relationship between chemical supplier and user: process improvement, innovation, and knowledge transfer. In leasing, in contrast, issues of process improvement or innovation or knowledge transfer play little if any role in the relationship between the chemical supplier and the user.

This does not mean that leasing operations cannot be part of a Chemical Leasing business model. Leasing operations can be economically justified in a broader Chemical Leasing business model when expensive chemicals can be recovered, as in the case of catalysts. But even in such cases, we need to be aware that it is highly unlikely that 100 percent of the chemical will be recovered.

The Chemical Leasing model aims at a more efficient use of chemicals in the production process by redefining the business relationship between the chemical user and the supplier.

Definitions: The “chemical user” is a company that uses chemicals and the “chemical supplier” is an entity in that company’s supply chain such as a manufacturer of chemicals and/or a distributor or trader of chemicals.

The conventional business model assumes that the more the chemical supplier sells, the more the chemical supplier earns. However, in the Chemical Leasing model the chemical supplier does not sell quantities. He or she sells the performance of the chemical. This is the purpose for which the chemical is applied.

For example, the performance of a chemical could be to clean or degrease metal parts, or to protect a surface. Payment is then made according to functional units, that is, the number of pieces cleaned, or the extent of area coated.

Example 1

A producer of automotive parts uses solvents to clean and degrease them. Under the Chemical Leasing model, the company pays the chemical supplier for the functions performed by the chemical, that is, the cleaning of metal parts. It pays per part cleaned to requisite quality levels. It does not pay according to the amount of solvent used.

Example 2

A car producer needs surface protection for its parts. This includes car body pre-treatment, surface activation and the application of a system of coatings, for all of which chemicals are used. Under Chemical Leasing, the company pays per car body protected. It does not pay according to the amount of chemicals used.

Example 3

A hotel needs to wash its laundry. The process uses detergents, disinfecting agents, and softeners. Under the conventional business model, the company would pay the chemical supplier according to the amount of chemicals used. Under Chemical Leasing, the hotel pays per kg of laundry washed to requisite levels of quality.

Example 4

A beverage producer needs to attach labels to its bottles. Under Chemical Leasing, the company pays the chemical supplier for the number of bottles labelled. The company does not pay according to the amount of chemicals used.

Chemical Leasing can be applied in many industries and processes, ranging from the textile industry to car manufacturing and even to agriculture.

Processes that are part of a Chemical Leasing plan are usually non-core processes in the company (e.g. cleaning operations, labelling of bottles in the beverage industry).

In Chemical Leasing, the supplier no longer measures success according to the volume of chemicals sold. The supplier and the user both benefit because less chemicals are used when payment is linked to the functions performed. By aligning the interests of supplier and user, the volume of chemicals used is reduced, costs are cut, and each party increases its profits.

Business decisions are driven by economic interests, as well as considerations of performance, risk, market position and competiveness. Particular forces and trends can motivate or even drive companies to search for sustainable technical solutions and innovative business models related to chemicals application.

Sustainability policy and environmental strategy. Following market trends, organisations are increasingly becoming aware of sustainability issues and developing their businesses in a sustainable manner. Such companies take care of their image as a “responsible company” and strive to achieve superior performance. The various activities and operations of such a company should be in line with their corporate policy. Chemical Leasing is a tool for the sustainable management of chemicals.

Technical progress in the chemical industry and, in particular, digitalisation is a driving force of change. Digitalisation facilitates the application of innovative business models, enabling companies to operate with chemicals more efficiently, improve control of resource consumption, easily record results and smoothly communicate with partners. It supports the application of the Chemical Leasing business model, in which the accurate recording of data is a key criterion for success.

Regulatory compliance has been recognised as a major driver of effective chemicals management. Many hazardous chemicals are in use in industry. Accidents and health and safety problems can become an important cost factor for the company management. There are growing costs related to safety issues, pressure from workers is growing, and changes to regulations on hazardous chemicals or to health and safety norms make compliance ever more demanding. Non-compliance can be costly and can even be a threat to a company’s continued existence. These pressures often push a company to search for innovative business and technical solutions. The Chemical Leasing business model can be just such an innovative solution.

High production costs in a process. High costs are often a key reason for a company to change its business model. Chemical Leasing helps optimise processes, increase productivity, and so reduce production costs.

Resource availability. Depletion of rare chemicals is a serious global problem, with the potential to impact the sustainability and competitiveness of a company. Implementation of the Chemical Leasing model has been shown to be an effective long-term solution.

Public pressure. The use of chemicals has increased dramatically due to economic development in various sectors. Consequently, people are exposed to a growing number of chemicals. As awareness of the risks related to hazardous chemicals grows, so does public pressure to substitute them. In general, final consumers can put pressure on a company to produce a more sustainable product, give better service and ensure business relations are conducted responsibly.

Supply chain demand. Many companies are integrated into supply chains, with management having to deal with demands made by their customers. Depending on the power they wield, companies at the head of supply chains may request or even demand that their suppliers follow their policy and apply a new business model.

Competition. Competition and market saturation can be important reasons for a company to seek to differentiate its business from others and improve its performance. Companies strive to find new approaches such as “green” PR and innovative strategies to win clients. Chemical Leasing boosts competitiveness and can help the company grow its market share or even enter a new market niche.

Role of the Supplier

In Chemical Leasing the supplier provides not only chemicals but also value-added services. The supplier’s responsibility is extended and may include management of the entire life cycle of the chemical.

The supplier provides experience and know-how on operating with chemicals effectively, efficiently and safely. The supplier partners with the user to optimise the way the chemicals are used in the user’s plants and prevent excessive use.

The supplier could optimise chemical use by advising on process optimisation and/or on chemical substitution to reduce health and safety and environmental risks.

Role of the User

The Chemical Leasing model allows the user of chemicals to concentrate on its core business while benefiting from the services and know-how of the supplier.The user is responsible for monitoring the process, recording the amount of units to be paid and respecting the process parameters defined by the supplier. In the event of changes to process parameters and/or equipment failure that may affect chemical consumption, the user is responsible for reporting this to its partner supplier.

Role of Other Parties

Other parties may be also involved. Their roles are defined on a case-by-case basis. For example, when the supplier and user seek to optimise a process, an equipment provider could be called in to replace obsolete technologies with resource-efficient ones or to introduce equipment for on-site recycling.

The basis of payment should be linked to the function of the chemicals and not to the quantities used. Chemical Leasing should adhere to the following sustainability principles:

Chemical Leasing aligns the interests and motivations of the chemical user and the supplier and helps achieve a win-win situation for them and the environment. The life cycle of the chemicals is prolonged, waste is minimised, and resources are used more efficiently.

The Chemical Leasing model encourages partners to exchange experiences and develop strong cooperation. It helps achieve economic, environmental and social benefits

Benefits for the Supplier

Benefits for the User

Chemical Leasing serves as a concrete tool to redefine and reorganise a business in line with circular economy principles.

By aligning the interests and motivations of the chemical user and the supplier, Chemical Leasing helps achieve a win-win situation for them and the environment. The life cycle of the chemicals is prolonged, waste is minimised, and resources are used more efficiently (while Chemical Leasing focuses on reducing the consumption of chemicals, the application of the business model often leads to reductions in the use of other resources such as water and energy). This contributes to the achievement of circular-economy goals.

Chemical Leasing can be applied in many industries and processes, ranging from food processing to car manufacturing and even to agriculture.

Chemical users have their key competence and know-how in the company’s core processes. Processes that are part of a company’s Chemical Leasing plan are usually non-core, support processes in the company, such as:

It is too costly to have full-time experts for such non-core support processes.

Note: Chemical Leasing can be applied to core processes as well, such as washing in laundries, growing of crops in agriculture or in other industries (see also below for an example from the textile industry).

Targeting “Suitable Processes”

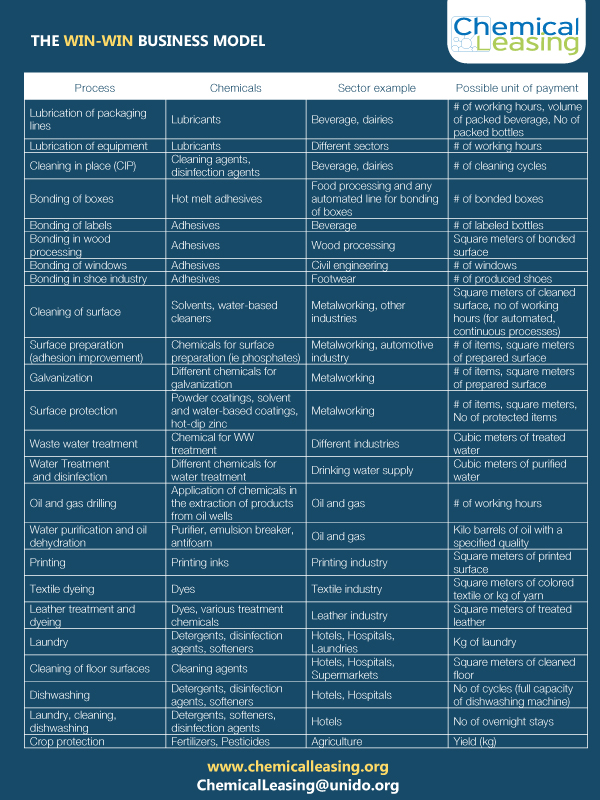

Table 1 below gives an overview of some suitable processes (this list is not exhaustive).

Note that certain processes and chemicals are not suited to Chemical Leasing. Examples are:

In addition, the target process should have potential for optimisation, through changes in the process and/or by chemical substitution.

Table 1. Overview of some suitable processe

For Chemical Leasing to be successful, the following nine elements are very important; the first three are critical.

(More information can be found in the section on Dos and Don’ts, Chemical Leasing Book (Section 7.3))

Practical considerations and examples related to the critical success factors

Factor 1: Excellence of Know-How

Suppliers must have additional process expertise to offer the users with respect to the target chemicals. For example, in the case of metal cleaning by solvents, users usually know how to use the equipment, when to change the solvent etc., but do not know the physics and chemistry underlying the process – what happens to the solvent during the cleaning process – and thus how to prolong the cleaning lifespan. Suppliers have this knowledge. They can therefore offer users the capability of optimising the cleaning process and so reduce chemical consumption. In addition, knowing better than users the toxic and hazardous properties of their chemicals, they can offer users new formulations that are less or non-hazardous to the environment and human health.

Example:

Valamar Laundry in Croatia purchased its laundry chemicals from the supplier Ecolab. The supplier has developed laundry chemicals that ensure the required washing quality at lower temperatures. Thanks to a knowledge exchange between the two partners, the process became more efficient and the quantity of laundry chemicals was reduced. Partners selected the unit of payment that corresponded to the key function of the chemical: kilogram of washed laundry.

Chemical Leasing does not benefit only users in terms of knowledge acquisition. It is a two-sided learning process. Often, suppliers gain experience on the workings of specific processes, thus further improving their know-how.

Factor 2: Appropriate Unit of Payment

It is not always easy to define a unit of payment. For example, in the metalworking industry, there are many different sizes and shapes of metal parts, different types of dirt to be cleaned (for instance, different types of oil used for different kinds of metal processing), so it is not possible to use cleaned surface or number of cleaned pieces as the unit of payment. However, cleaning machines work continuously, and the number of working hours is a solution for a unit of payment that can be measured, recorded and demonstrated.

Picture 1. Metal parts of different sizes and shapes

Factor 3: Constant Monitoring of Unit of Payment

It is important to have a unit of payment which can be accurately monitored, recorded and demonstrated. For example, in the case of conveyor lubrication, the unit of payment is the number of working hours of the conveyor (this corresponds to the function of the chemical, which is to ensure that the belt works smoothly). To control the number of working hours, Ecolab, the supplier of Knjaz Milos in Serbia, installed a counter for working hours (only the supplier can make modifications to the equipment). This counter measures, records and demonstrates the units of payment, the number of working hours of the conveyer.

Picture 2. A counter for working hours

The implementation of Chemical Leasing can be supported by:

Some of the factors that make implementation of Chemical Leasing difficult are listed below:

Differences between Chemical Leasing and Other Business Models

| Business Model | Scope | Cooperation between parties | Payment | HSE requirements | Process improvements and chemical substitution | Innovations |

|---|---|---|---|---|---|---|

| Chemical Leasing | Specific process (one or more in a company) at the company site. | Exchange of know-how and experiences between partners. Shared goals, User runs the process. | Based on chemical performance and function, includes chemical and sometimes equipment leasing. | HSE have to be improved. | Process is improved. Chemicals substituted by others with similar or less hazard. Recycling can be included. | Acceleration of process innovation and creation of added value for all partners. |

| Outsourcing | Specific process, usually one in a company, at the company site or outside. | User just pays for the service. Does not run the process or is otherwise involved in it. | Based on services provided – includes chemicals, work, maintenance, other resources*. | There are no HSE requirements. User has no information on chemicals that are being used in the process. | There is no request for process improvement. Chemicals could be substituted by more hazardous ones. | There are no requirements for innovation. |

| Chemical Management Services | Management of all chemicals in use, at the company site. | Service provider takes overall activities related to chemicals (purchase, quality control, storage). Shared goals. | User pays for a menu of different services. | Service provider usually provides HSE management related to chemicals. | Process improvements and/or chemical substitution are usually not included in the contract. | There are no requirements for innovation. |

| Take-back chemicals | Specific process (one or more in a company) at the company site. | Exchange of know-how and experiences between partners. Shared goals. User runs a process. | Based on chemical function. | HSE is usually improved. | Process is improved, waste chemicals are recycled. | Acceleration of process innovation and creation of added value for all partners. |

| Classical Leasing | Specific chemical that is not consumed in a process. | There is no technical cooperation between partners. | User pays leasing fee. | There are no HSE requirements. | There is no request for process improvement. There is no chemical substitution. | – |

*Unit of payment in Chemical Leasing and outsourcing could be the same (i.e. in water treatment: cubic meters of treated water).

When you visit our website, it may store information through your browser from specific services, usually in the form of cookies. Here you can change your Privacy preferences. It is worth noting that blocking some types of cookies may impact your experience on our website and the services we are able to offer.