When you visit our website, it may store information through your browser from specific services, usually in the form of cookies. Here you can change your Privacy preferences. It is worth noting that blocking some types of cookies may impact your experience on our website and the services we are able to offer.

The Chemical Leasing business model is intended to generate a sustainable business and to support long-term working relationships between the partners. It is therefore important to consider modifications and corrections if the business develops differently to expectations. It is also important to be flexible enough to adapt business activities continuously based on results.

Task 10 aims to manage this process, facilitating corrections and further optimizing chemical use in the company’s production process.

Monitoring is in principle a continuous process that needs to be performed once a Chemical Leasing contract is established. It provides both partners with data on:

Table 4 on baseline data collection can be extended and adapted for the recording of monitoring data (e.g. some companies might need to add process parameters such as temperature and pressure).

Monitoring activities should be agreed between the partners and the results should be shared in a transparent way in order to maintain trust and facilitate joint decisions on modifications.

The supplier should be able to confirm whether the producer’s report on the number of units to be paid corresponds to the real situation, e.g. if the company pays per cleaned pieces, the number of pieces cleaned should be verified.

Monitoring results must be well documented and communicated between the partners as they might form the basis for later contract modifications.

The evaluation should compare the baseline data (before implementation of the Chemical Leasing model) with current data to assess real achievements. The evaluation should answer the questions:

The result of the evaluation can be:

An evaluation schedule must be agreed between the contractual partners. A three- to twelve-month evaluation period is recommended. (Shorter periods require excessive effort and the results might not be stable. Longer periods might cause corrections to come too late.)

The company might want to present its achievements after a certain period of applying a Chemical Leasing model: this could be useful, for example, for the company’s annual report; for speeches and meetings with stakeholders; for ISO 9001, 14001, EMAS and CSR reports; for corporate news, leaflets and presentations; and for meetings with the supplier to discuss contract extension.

The results can be presented in different formats, e.g. in a “before and after” comparative table and photograph (see Figure 5) or in a short summary of the results achieved, as shown in Table 5.

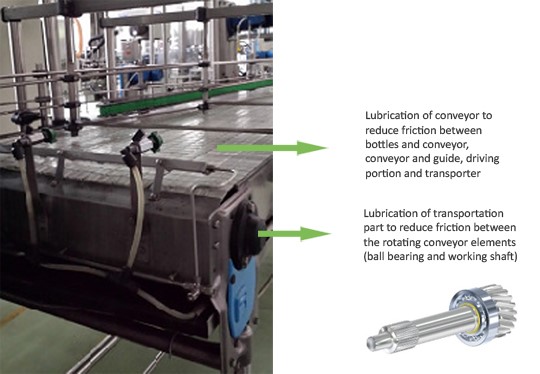

Picture 5. The same packaging line before and after implementation of Chemical Leasing for conveyor lubrication

Table 5. Sample summary table of results

| Economic figures | Environmental improvements | Safety and health improvements |

|---|---|---|

| • Savings planned and achieved • Change in product output • Return on investments/Payback period |

Change in pollution intensity: Reduction in: • Consumption of chemicals • Hazardousness of chemicals • Water consumption • Waste water generation • Energy consumption • Waste generation |

• Reduction in accidents related to the handling of chemicals • Reduction in adverse health effects in workers due to exposure to chemicals |

| Intangible benefits (For example, The company can better control and predict the costs related to the target process.) |

||

Very often partners start by implementing the Chemical Leasing model in one particular line or area. With time, if the cooperation between the partners is positive and the user’s expectations are met regarding the costs, the results, and the quality of the products and services, the user can decide to extend the model to other production lines and areas.

Having finished Task 10 you are aware of results achieved and have developed a basis for continuous improvement.

In Task 1 you identified potential chemicals and processes for Chemical Leasing. Now, you need to pre-assess them to determine whether the Chemical Leasing business model would be relevant. This is the objective of Task 2.

Keep in mind that the change from your existing business model might require additional efforts and resources; therefore, it is important to determine whether there are economic or other reasons that justify implementation of the new model.

Also keep in mind that the decision to implement the Chemical Leasing model should be grounded on the following criteria for sustainability:

One company might have several processes and chemicals which could be “suitable” for Chemical Leasing implementation. For example, if the company is a beverage producer, it might use chemicals for lubrication, cleaning, disinfection and bonding, all of which are suitable/relevant for Chemical Leasing. Furthermore, different chemicals can be applied in the same process. These chemicals need to be pre-assessed individually.

Picture 1: Conveyor lubrication

Picture 1: Conveyor lubricationSome chemicals have hazardous properties and can have negative impacts on human health and/or the environment. You should consider these, as well as economic factors, when pre-assessing the chemicals. Each chemical should be analyzed (“pre-assessed”) based on three parameters: quantity consumed, cost and hazardousness.

Parameter 1 – Quantity consumed

Define the amount of the chemical consumed annually in a given process and assign the chemical “points” as shown in the chart below. The greater the quantity of a chemical used, the higher the general suitability for Chemical Leasing.

| Quantity of chemical X applied | Recommended criteria | Points |

|---|---|---|

| High | More than 100 tons/year | 5 points |

| Medium | More than 10 tons/year | 3 points |

| Low | More than 1 tons/year | 1 points |

Parameter 2 – Cost

Check the annual purchasing cost of the chemical and assign the chemical “points” as shown in the chart below. The higher the cost, the higher the general suitability for Chemical Leasing.

| Cost of chemical | Recommended criteria | Points |

|---|---|---|

| High | More than €100,000/year | 5 points |

| Medium | Between €100,000 and €10,000/year | 3 points |

| Low | Less than €10,000/year | 1 points |

Parameter 3 – Hazardousness

Most chemicals present some degree of hazard, such as toxicity, flammability, or corrosiveness. The greater the hazard associated with a given chemical, the greater the need to optimize its use or to consider substitution with a less hazardous/lower risk alternative. Identify each chemical’s hazardousness and assign the chemical(s) “points” as shown in the chart below. Information about a chemical’s hazardousness can be found on the product label. The detailed information can be found on the product Safety Data Sheet (SDS), which can be obtained from the supplier.

| Hazardousness of chemical X | Relevance | Points |

|---|---|---|

| High | Hazardous chemical of high or potential concern | 5 points |

| Medium | Chemical that have hazardous property(is) (for example, chemical is corrosive, flammable etc) | 3 points |

| Low | Non hazardous chemicals | 1 points |

Calculating the final score

Add up the points in the three charts to give each chemical a final score.

A company with a lubrication process consumes lubrication chemicals in high volumes, the costs are estimated as medium and hazardousness as low. The final score will be: 5+3+1=9

You may repeat this procedure for other chemicals and processes.

With this Task done, you have completed the pre-selection and pre-assessment of chemicals and processes which can provide you with promising Chemical Leasing cases.

Continue with Task 3 – Pre-defining the unit(s) of payment

This task involves gathering all relevant data to describe the current situation in the selected process (e.g. one of the production lines) before implementation of Chemical Leasing. The data are needed to establish a baseline that is used to evaluate the results: the costs and benefits of implementing Chemical Leasing, over a given period of time.

In gathering the data, the Chemical Leasing team should be aware that:

To establish a baseline it is necessary to define indicators relevant to the selected process. The indicators should be specific, measurable, available/achievable in a cost effective way, relevant, and time-related (SMART), and they should be the same as the indicators used in monitoring and evaluation (task 10)

Information about indicators can be found here.

Table 3. Examples of indicators for target processes

| Economic indicators | Environmental indicators | Health and safety indicators |

|---|---|---|

| Costs for materials, energy, water, waste-water treatment, waste management, etc. | Input: • Chemical consumption • Water consumption • Energy consumption • Waste water generation • Waste generation • Air emissions • Pollution intensity |

Accidents related to the handling of chemicals Adverse health effects in workers from chemical exposure |

Table 4. Example of baseline data collection for a specific industrial process: lubrication of the PET bottle packaging conveyor.

To ensure the smooth movement of bottles during packaging, the conveyor belt has to be lubricated. The current process uses a lubricant dissolved in water.

| Input | Unit in l, m3, kg, etc./year | Comments |

|---|---|---|

Lubricant

|

e.g.: The idea is to change to a dry lubricant that does not need water | |

Sodium hypochlorite

|

volume per year | |

| Water for the lubricant | m3 per year | |

| Chemicals for waste water treatment | volume per year | |

| Energy | Not relevant for this case | |

| Output | Unit in l, m3, kg, etc./year | |

| Waste-water | m3 per year | |

| Waste Packaging waste for the lubricant | number of packages | |

| Economic data | Unit in €, $, local currency/year | |

| Costs for lubricant | Euro (or other currency) per year | |

| Costs for sodium hypochlorite | Euro (or other currency) per year | |

| Costs for water | Euro (or other currency) per year | |

| Costs for waste water treatment chemicals | Euro (or other currency) per year | |

| Costs for energy | Not relevant for this case | |

| Costs for waste water treatment | Euro per year | |

| Costs for waste disposal/treatment | Euro per year | Not relevant for this case |

| Social data | Unit | |

| Number of jobs in the process | Nr of people working on the line per shift | |

| Working conditions: Aerosols in the air – risk of worker exposure Slippery floor – risk of injuries Lubricant is manually applied – risk of worker exposure |

The baseline data is the starting point for development of the Chemical Leasing and any subsequent monitoring and evaluation.

▶ When you have defined the baseline for the process, continue with Task 7 – Define measures to optimize chemical use and processes

In Task 7, the Chemical Leasing team will analyze the options for optimizing chemical use in the selected process(es).

Available benchmarks e.g. BREFs might be considered. For this task it is important to apply the sustainability criteria, which exclude the substitution of higher risk chemicals for chemicals currently used. There are three possible approaches:

Ideas for optimization should be evaluated against expected advantages and disadvantages, yielding a list of “most promising” measures. A detailed cost benefit analysis of these measures should be undertaken that includes other savings from the optimization of chemical use. Such savings, for example from a reduction in the use of water, energy and materials and in the production of waste, can be quite significant.

The conveyor belt in a beverage company shown in Picture 1 and Table 4 provides an example. The Chemical Leasing team in this real-life case considered several possibilities to improve the lubrication process, which was using a lubricant dissolved in water.

In its analysis of the investments (costs) and benefits of the three options, the Chemical Leasing team concluded that the investments for option 2 would be much higher than the investments for option 1, but that the economic, environmental, and health and safety benefits would be considerably higher for option 2 (due to less chemical consumption, no water consumption, lower waste water treatment costs, better working conditions, etc.). The analysis showed that option 2 was the most sustainable and sound, and that the investments needed for shifting the lubrication process to the dry lubricant would be paid back in 2 to 3 years. Process optimization, option 3, was considered as well but the savings were less than with the first two options.

As result, the team decided on option 2, noting that option 3 could be done as a supplementary measure if the existing equipment was not changed (in fact, the line was regularly maintained and there was no leakage). The company had 80 nozzles at the target production line, the average consumption of water per nozzle was 5 litres/hour, and the line is in operation 3500 hours/year, so the yearly consumption of water was 1400 m³. This water was saved thanks to the change to a dry lubricant.

Continue with Task 8 – Test the identified options

The third task is to identify possible units of payment based on the services rendered by the chemicals.

As previously noted, Chemical Leasing is based on a shift from a volume based payment (e.g. $/t of chemical) to a benefit oriented payment (e.g. $/m2 cleaned surface). Table 2 provides examples of possible units of payment in different industry sectors and processes.

Table 2. Possible units of payment for different processes

| Categories of chemicals | Processes | Possible unit of payment | Sectors/Subsectors |

|---|---|---|---|

| Adhesives | Packaging/Bonding | • Number of bonded pieces • Bonded square meters |

• Food and beverage sector • Construction of buildings (e.g. for bonding of windows) • Manufacture of footwear • Manufacture of wood products |

| Labeling | • Packed (labeled) bottles • Bonded square meters of label |

Food and beverage sector | |

| Detergents, disinfection materials | Cleaning/ Washing |

Occupied room | • Accommodation (Tourism) sector • Healthcare sector |

| Number of cleaned (disinfected) bottles | Food and beverage sector | ||

| Solvents and detergents | • Cleaned pieces Cleaned area • Working time /operations (see note below) |

• Manufacture of fabricated metal products • Automotive industry |

|

| Detergents, disinfection materials | Laundry | Kg of laundry | • Accommodation (Tourism) • Healthcare sector |

| Oils, greases | Lubrication | Working hours | Mining and quarrying |

| Other types of lubricants | Lubrication of packaging conveyor | • Working hours of conveyor • Packed product |

Food and beverage sector |

| Powder coatings, solvent- and water-based paints, chemicals for phosphating | Surface protection | • Square meters of treated area • Number of pre-treated/painted products |

Manufacture of: • fabricated metal products • vehicles and machinery • wood products • electrical equipment • rubber and plastic products |

| Inks | Printing | Printed copy | Publishing and printing |

| Coagulants, Flocculants, defoamers | Waste water treatment | Cubic meters of treated water | Different sectors |

| Bore hole chemicals (Calcium bromide, zinc bromide, caesium formate) | Oil drilling | Daily fee | Oil and gas field services |

| Catalysts | Chemical reactions | t of synthesized product | Manufacture of chemicals and chemical products |

As the table illustrates, in some cases the unit of payment may be based on the operating hours (working time) of equipment rather than on the direct services rendered by the chemicals. For example, in the production of metal parts, there are many parts with different shapes and sizes. It would be difficult to apply as a unit of payment the number or surface area of cleaned parts, and would make more sense to relate the unit of payment to operating/working hours.

Picture 2: Different sizes and shapes of metal parts

Once the chemicals and units of payments are pre-defined, it is essential to check which measurement devices, equipment, and/or information are required to measure, monitor and verify these units of payment. In some cases, several options are possible. The supplier should be able to check whether actual results/outputs correspond to reported figures.

Example

For the lubrication process of a packaging conveyor, the unit of payment could be the number of working hours of the conveyer but also the number of packed bottles. To monitor the number of working hours, the supplier could install a counter on the packaging line (see Picture 3). To monitor the number of packed bottles, the supplier would need to have access to the production company’s database, to check how many bottles were produced.

Picture 3: A counter on the production line

Continue with Step 2 – Development and implementation

Task 4 is to create a committed internal working group that will develop and implement the Chemical Leasing model and will become a driving force in all of the developmental changes.

The group should at a minimum include members from the company’s production and purchasing departments. Ideally it should also include members from the R&D department, the quality assurance department, the legal department, the financial department, the health and safety and environmental department, and potentially members of the management board.

The importance of the working group cannot be overestimated. Success in modifying and optimizing the company’s processes will depend on the efforts of these people and their knowledge, efforts, and understanding of the company´s strengths, weaknesses and potential problems. A skilled team that collaborates well is an absolute necessity for successful implementation of a Chemical Leasing business model.

As soon as the internal team is established, it is essential to set-up the core Chemical Leasing team which should include the supplier(s) and eventually other partners. This will facilitate the further development of the Chemical Leasing model and the exchange of know-how.

Continue with the Task 5 – Establish a core Chemical Leasing team

As soon as the internal working group is established, task 5 is to set up a core Chemical Leasing team that includes the supplier(s) and possibly other partners. This team will facilitate the further development of the model and the exchange of know-how.

The role of the core Chemical Leasing team is to:

The process of creating the core team should begin with a discussion of the Chemical Leasing model with the supplier(s) of the chemicals and processes selected in Step 1. During the discussion you should present your ideas about possibilities for optimizing chemical use and also ask the supplier(s) for their ideas. If a supplier does not have the necessary knowledge and skills to support chemical optimization or is not willing to accept a Chemical Leasing business model, you might consider changing suppliers for the target process.

Under the Chemical Leasing business model, the supplier is intricately involved in process optimization, providing not just the chemicals but also know-how on how to optimize their consumption and/or replace hazardous chemicals with less hazardous/lower risk alternatives. Often the supplier can provide training on site and can recommend equipment changes, upgrades and/or installation.

When selecting a supplier for the core Chemical Leasing team, be aware that you may have the possibility of choosing between several partners (chemical manufacturers or distributors) in the supply chain. In addition, if your company has a procurement department, be sure to apply its internal policy, which might require you to initiate an individual or public bidding process for potential suppliers. Also be aware that other partners could be included in the core team, such as equipment and plant suppliers, recycling and disposal companies, and financial institutions.

Three models of interaction between different numbers of partners are shown in the diagram below. Model A illustrates the basic form of Chemical Leasing, with an intensified collaboration and knowledge exchange between a chemical supplier and user. Model B includes the equipment supplier in this exchange (and the option of “classical” leasing of equipment). Model C extends the collaboration to further partners such as recycling companies or financial institutes. As the leadership of such a group becomes more and more difficult, in practice joint ventures or consortia are typically formed.

Picture 4. Models of cooperation

Once the work plan is defined and concrete ideas have been developed for process optimization and/or substitution, the team should begin to collect data and define the baseline.

Continue with the Task 6 – Collect data and define the baseline

For Consultants

Core competence: Supports/promotes/facilitates the establishment of a ChL contact

Benefit: Portfolio development and new business opportunities

Under a Chemical Leasing model, a third-party consultant must have knowledge of industrial process optimization, innovative business models, and the efficient use of chemicals. The consultant must be able to provide the chemical supplier and user with value added that exceeds the cost of the consulting service.

Consulting companies who have the necessary knowledge and expertise and who wish to pursue ChL are encouraged to consult the Chemical Leasing step-by-step guidelines on initiating and implementing a ChL business model as well as helpful instruments of this toolkit. model. Use of the toolkit is particularly important for consultants who wish to initiate the development of a ChL model with potential clients.

For consulting companies, potential benefits of learning and applying the ChL model include:

The first task is to collect information on the chemicals used in your company and the related costs.

This should include data on:

The information collected should not include data on:

Processes that are part of a Chemical Leasing plan are often non-core processes in the company, such as:

Table 1 below provides an overview of chemicals, processes, and sectors where Chemical Leasing has been applied successfully, based on information available to UNIDO up to 2014. The list is not exclusive but is intended to help companies identify potential areas for Chemical Leasing application.

Table 1. Chemicals, processes, and sectors to which Chemical Leasing has been applied successfully

| Categories of chemicals | Processes | Examples of sectors/subsectors |

|---|---|---|

| Adhesives | Packaging/Bonding | • Food and beverage sector • Building construction (e.g. for bonding of windows) • Manufacture of footwear • Manufacture of wood products |

| Labeling | Food and beverage sector | |

| Detergents, disinfection materials | Cleaning/washing | • Accommodation (Tourism) sector • Healthcare sector |

| Food and beverage sector | ||

| Solvents and detergents | • Manufacture of fabricated metal products • Automotive industry |

|

| Detergents, disinfection materials | Laundry | • Accommodation (Tourism) sector • Healthcare sector |

| Oils, greases | Lubrication | Mining and quarrying |

| Other types of lubricants | Lubrication of packaging conveyor | Food and beverage sector |

| Powder coatings, solvent – and water-based paints, chemicals for phosphating |

Surface protection | Manufacture of: • fabricated metal products • vehicles and machinery • wood products • electrical equipment • rubber and plastic products |

| Inks | Printing | Publishing and printing |

| Coagulants, flocculants, defoamers, | Waste water treatment | Different sectors |

| Bore hole chemicals (e.g. calcium bromide, zinc bromide, cesium formate) |

Oil drilling | Oil and gas field services |

| Catalysts | Chemical reactions | Manufacture of chemicals and chemical products |

The identified processes and chemicals are the basis for further analysis.

If you have identified potential chemicals and process(es), continue with Task 2 – Pre-assess chemicals and processes

For Supplier

Core competence: Know-how about application of different chemicals

Benefit: Long-term business partnership and better market competitiveness

Under a Chemical Leasing model, the supplier can be a manufacturer of chemicals and/or a distributor/trader of chemicals. In either case, the supplier should have in-depth experience and knowledge of the chemicals sold and how to use them most effectively, efficiently and safely. Based on this, the supplier should be able to provide advice and services for improving the way the chemicals are used in their clients’ plants.

A supplier who wishes to initiate the development of a Chemical Leasing model and engage potential partners should carefully consult the guidelines presented in this toolkit and consider how they can be adapted (in particularly the tasks from 1 to 4): The supplier should start the process by checking the chemicals it supplies to clients (chemical users), and identifying clients who have the highest potential for the Chemical Leasing model. The supplier may then initiate the negotiation process. If the clients express interest, both partners can jointly follow the provided methodology and address relevant steps and tasks together, flexibly adapting the tasks as necessary.

Potential benefits of the Chemical Leasing model for the supplier are:

The final task before actually implementing the optimization option(s) is to establish a contract between the chemical user and supplier.

Every company has its own contractual standards and forms, but to facilitate implementation of a Chemical Leasing contract, the key elements listed below should be included. It is advisable to begin with only one production line for a certain period of time, and if it goes smoothly, to extend the Chemical Leasing model to other lines.

Key elements for a Chemical Leasing contract:

If you have signed a contract and are interested in how to monitor and evaluate the results of the Chemical Leasing implementation, go to Step 3 – Monitoring and evaluation.

Task 8, testing of the identified options, should prove the applicability of the Chemical Leasing model in the selected process, provide concrete figures for costs and savings, and demonstrate that quality requirements are met.

The design and the plan of the testing should be defined by the core Chemical Leasing team and should take into consideration:

Unit of payment:

The testing should also cover the new unit of payment that was identified in Step 1. This unit should now be analyzed and verified in practice. In addition, at the end of the testing process, the Chemical Leasing team must agree on the price per unit of payment (for example: 1 Euro/ m2 cleaned surface). In comparing the costs of traditional and Chemical Leasing models, it is important that the calculations be based on real costs related to chemical use (energy, water, etc.) and that they take into consideration all potential savings that can be achieved under Chemical Leasing.

The testing should result in:

If the testing has been successful and the price determined, continue with Task 9 – Establish a contract

For User

Core competence: Know-how about the company’s key industrial process and final product

Benefit: Economic, environmental, health and safety benefits; better chemical management

The potential benefits of a Chemical Leasing model for companies that use chemicals in their processes are considerable. They might include:

The benefits are especially important when chemical use is not part of the company’s core processes (e.g. glue for packaging in the food and beverage industry, washing chemicals for laundry in hotels). The Chemical Leasing model allows such companies to concentrate on their core business while benefiting from the service and know-how provided by the supplier.

Chemical users who wish to pursue ChL are encouraged to consult the Chemical Leasing step-by-step guidelines on initiating and implementing a ChL business model as well as helpful instruments of this toolkit.