How ‘Leasing’ Chemicals Can Contribute to A Cleaner Environment

One innovative way that chemicals can be produced and used in ways that minimize significant adverse impacts on human health and the environment is through Chemical Leasing. At the heart of the Chemical Leasing model is the idea that economic success no longer depends on the volume of chemicals sold, but on the service that is linked with the chemicals.

Key Words: Sustainable Development Goals, chemical management, environmental impact, resource efficiency, resource consumption, chemical industry, Chemical Leasing

Given that chemicals and waste affect all aspects of development, the sound management of both is key to achieving a number of targets under the UN Sustainable Development Goals. And one innovative way that chemicals can be produced and used in ways that minimize significant adverse impacts on human health and the environment is through Chemical Leasing.

Originally initiated by the United Nations Industrial Development Organization (UNIDO) and the Austrian Government in 2004, Chemical Leasing is based on an alternative approach that turns the conventional business model – which assumes that the more you sell, the more you earn – upside down. At the heart of the Chemical Leasing model is the idea that economic success no longer depends on the volume of chemicals sold, but on the service that is linked with the chemicals. Here, the supplier does not sell quantities, but rather sells the performance, the function of the chemical. This is the service rendered by the chemical or the purpose for which the chemical is applied.

And it’s not just for chemicals. Realistically, nobody buys electricity or gas on account of the fact that the product is “interesting” – what is interesting is the “service” the product renders – in this case, providing energy in the form of light, heat, or power.

If an energy supplier no longer offers “electricity” but instead offers “light”, the company’s primary economic goal will be to produce this service – lighting – with as small an amount of energy as possible. In a resource-efficient industry, producers no longer sell their products, but rather the performance (service) of the product in partnership with the user. Equally, a producer of electric light bulbs will no longer sell light bulbs but offer “lighting” in a partnership with an energy provider. Thus, every participant has an interest in achieving the service of “lighting” on the basis of an optimum use of energy and light bulbs, rather than selling as many light bulbs and as much energy as possible.

The primary industry as well as the entire subsequent value chain, including trade, must become part of these business models and question existing paradigms. If the primary industry itself is a player in the new business model, value is created through performance (service) rather than the sale of products. Providing the service offered on the basis of an optimum use of resources will thus be in the economic interest of all partners involved, including the producing sector.

Technological trends such as digitalization are putting additional pressure on the primary industry by dramatically increasing the demand of efficient use of materials. Even the construction and minerals industries will not be able to do without service-based approaches, and will have to make the shift from offering construction materials alone to providing entire building and construction concepts in cooperation with planning and construction businesses. This is the only way for them to turn the pressure on resource efficiency into their own economic advantage.

And let’s be honest, processing companies and consumers alike are not interested in “owning” say detergents or paint. Rather, these products provide services, such as clean surfaces or painted walls. For example, if a supplier of chemicals manages to perform an agreed service (cleaned parts, coated surfaces) on the basis of a smaller amount of chemicals, this will turn into a profit-maximizing factor for the chemicals supplier. At the same time, thousands of tons of chemicals will have been avoided – chemicals that did not need to be synthesised, processed and disposed of – saving a tremendous amount of resources and thus lower carbon dioxide emissions from the process.

This is a win-win situation – an increase in the efficient use of chemicals while reducing the risks of chemicals and protecting human health. It has also shown to enhance productivity, contribute to tighter processes and longer customer retention, as well as significantly reduce resource consumption. This is good news for companies and their profits, but also good for the environment.

- More information about Chemical Leasing

- Learn more about the Global Chemical Leasing Award 2021

Source: The article was published for the first time in:

www.greengrowthknowledge.org/blog/how-%E2%80%98leasing%E2%80%99-chemicals-can-contribute-cleaner-environment

Image copyrights: Adobe Stock

Thomas Jakl

Deputy Director-General

Ministry of Environment of Austria (BMK)

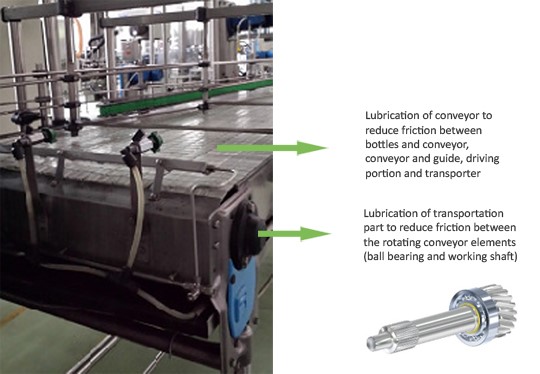

Picture 1: Conveyor lubrication

Picture 1: Conveyor lubrication